Bolivar Mine, Bolivia

-

Overview

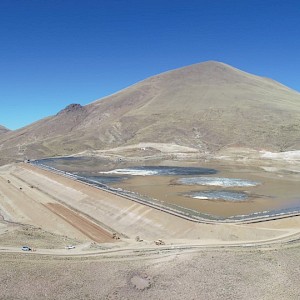

An underground silver-zinc-lead mine located in Antequera near Oruro City, which was first mined in 1810. The current mine complex is comprised of an underground mine, concentrator plant, maintenace workshop, shaft-winder, tailings storage facility, water treatment plants, supplies warehouse, main office, hospital, and camp.

The mine currently employs about 600 individuals and mining has been fully mechanized since he start of 2020 as a part of a broader safety initiative.

-

Location

Bolívar Mine is located in the state of Oruro in Bolivia, and municipality of Antequera. Paved roads connect Bolivar to the capital city La Paz (298 km), Oruro City (75 km) and Poopó Rail Station (22 km) which is the concentrate warehouse and dispatch.

Bolívar Mine, located within the municipality of Antequera is important to the neighboring communities of Antequera, Charcajara, Chapana and Quea Queani. The community of Antequera is immediately adjacent to the mine site and the largest community in the area of influence. The town is inhabited mainly by mine workers. Historically, it has been an area of intensive zinc, lead and tin mining so support, and service businesses have established themselves to serve the mine and its employees.

-

Operations and Infrastructure

Paved roads connect Bolivar to the capital city La Paz (298 km), Oruro City (75 km) and Poopó Rail Station (22 km). Concentrates are transported by truck from Bolivar process plant to the rail station at Poopó (concentrate warehouse and dispatch) from where it is transported to a warehouse at Portezuelo outer Harbor, located 35 km from the city of Antofagasta, Chile.

In addition to a network of paved roads, Bolivar also has access to rail for concentrate transport. Concentrate is hauled 22 km to the Poopó railway station with the trucking service contracted from local owners to help support the economin development of neighboring communities.

The mill uses a crushing, grinding, and flotation flowsheet to recover a lead concentrate and a zinc concentrate. Both concentrates are sold to the Antafagasta smelter in Chile. The mill receives feed from 2 sources; the company mining operation and toll milling purchased through San Lucas. The mill processes the 2 types of feed separately which allows for an analysis of processing for both types of feed.

The mine's electricity is supplied from the national grid with a 2.8MW diesel backup at the mine available for the plant thickeners and mine dewatering. The mine produces an excess of water from the underground mine. The water is than treated in separate plants for two different uses: one for potable water at the mine and surrounding communities, the other for industrial use in the mine and process plant.

-

Geology, Mineralization & Exploration Potential

The Bolivar Mine is located in the Cordillera de los Azanaques, forming the western edge of the Cordillera Oriental, which is detached from the Cordillera de los Frailes, belonging to the group of central mountain ranges. Characterized by the essence of undulating plateaus, outstanding mountains parallel to the course of the Andes, with elevations that vary between 3,400 and 4,600 msnm. The area is part of the polymetallic belt of the altiplano and the Cordillera Occidental.

It is located in Cenozoic rocks of the middle to upper Silurian, constituted almost entirely by marine sediments of variable depth: from infraneritic, neuritic and bathyal environments.

The Bolivar system is a network epigenetic hydrothermal base metal type veins and faults filled mineralization hosted within a variety of lithologies from volcanic tuffs to sedimentary packages. The main mineral assemblages are composed of sphalerite, marmatite, galena, silver-rich galena and silver sulfosalts.

-

Mineral Reserves & Resources

Grade Contained Metal Tonnes

(kt)Ag

(g/t)Zn

(%)Pb

(%)Ag

(koz)Zn

(kt)Pb

(kt)Measured Mineral Resources 855 327 12.78 1.37 9,003 109.3 11.7 Indicated Mineral Resources 677 295 12.24 1.25 6,426 82.9 8.4 Measured & Indicated Mineral Resources 1,532 313 12.54 1.32 15,429 192.2 20.2 Inferred Mineral Resources 4,202 403 10.35 1.00 54,436 434.8 41.9 Proven Mineral Reserves 742 299 10.65 1.31 7,144 79.1 9.7 Probable Mineral Reserves 495 233 8.92 0.97 3,705 44.1 4.8 Proven & Probable Mineral Reserves 1,237 273 9.96 1.17 10,849 123.2 14.5 Notes:

- The Mineral Resource estimate was prepared using a 10.6% zinc equivalent cut-off grade. Cut-off grades were derived from $25.20/oz silver, $1.38/lb zinc and $1.20/lb lead, and process recoveries of 91% for zinc, 70% for lead, and 89.7% for silver.

- The Mineral Reserve estimate was prepared using a 12.7% zinc equivalent cut-off grade, using the formula ZnEQV = Zn% + 0.7 x Pb% + 0.046 x Ag (g/t). This cut-off grade was based on current smelter agreements and metal prices of $21.00/oz silver, $1.15/lb zinc and $1.00/lb lead, total OPEX costs of $120.22/t based on 2022 actual costs plus capital costs of $48.68/t, with process recoveries of 91.0% for zinc, 70.0% for lead, and 89.7% for silver.

- Bolivar and Porco Mines are part of the Illapa Joint Operation with COMIBOL. Bolivar and Porco are presented at 100% production, whereas the Company records 45% of revenues and expenses in its consolidated financial statements. The Joint Operation agreement expires in 2028.

- The effective date of the Mineral Resource and Reserve estimates at the Bolivian Producing Mines is January 1, 2023. Production data for the calendar year 2023 has been included in Section 24 of the various NI 43-101 compliant technical reports for the Bolivian Producing Mines and shows the depletion and typical replenishment of resources and reserves over a calendar year.