Caballo Blanco Group of Mines, Bolivia

-

Overview

As a unit, Caballo Blanco produces about 850 t/d of mineralized material. Approximately 60% of mine production is generated by conventional shrinkage and cut & fill methods. The remainder is produced by more modern trackless sublevel stoping. Run-of-mine mineralized material is hauled to the Don Diego Process plant in dump trucks.

All three mines are exploiting the same mineralized trend with potential to further develop common infrastructure and other shared services.

Mine labor totaled approximately 275 full time employees for the past several years.

-

Location

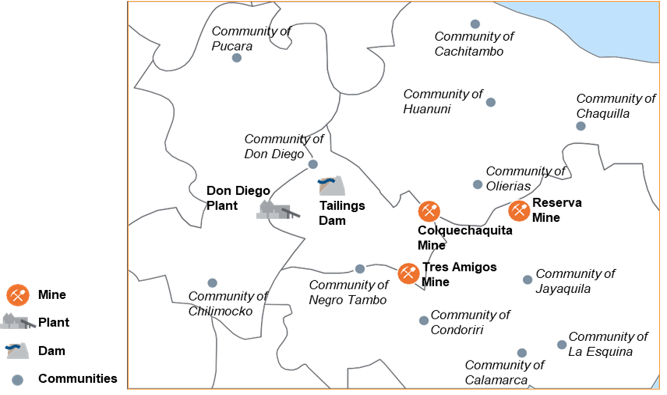

The Caballo Blanco project consists of three separate mines and one process plant operating as one to produce Zinc and Lead concentrates. An Important part of the supporting infrastructure includes 2 off-site power plants that produce supplemental electric power to the mines. The mines are relatively close together and located as follows:

Reserva and Tres Amigos Mines are located 31 km southeast of the city of Potosi, in the Canton Concepcion of the first section of the Tomas Frias Province of the Department of Potosi, at an average elevation of 4,536 masl, at UTM coordinates WGS-84: 218764E and 7814967N.

Coquechaquita Mine is located 30 km southeast of the city of Potosi, in the Canton Concepcion of the first section of the Tomas Frias Province of the Department of Potosi, at an average elevation of 4,520 masl, at UTM coordinates WGS-84: 219915E and 7819380N.

The Don Diego Process plant is located about 23 km Northeast of the city of Potosi, in the Don Diego Canton, Municipality of Chaqui, Cornelio Saavedra Province, of the Department of Potosi. At an elevation of 3,550 masl at UTM coordinates WGS-84: 228933E and 7841150N.

There is a 60 km drive from the mines to the Don Diego Processing plant.

-

Operations & Infrastructure

Reserva mine is the youngest and most modern of the three mines. Mine production is about 275 t/d. All mining is done with sublevel longhole methods and trackless development. In principle, the AVOCA method being used has all the productivity advantages of longhole stoping and allows for concurrent backfill to continuously support the hanging wall. Backfill for stoping is generated from the development mining.

Colquechaquita mine has been in production since 1991 using tracked development and conventional shrinkage and cut and fill stoping methods. The mine produces about 230 t of mineralized material per day. The transition to mechanized mining is in process but still in the early stages. Much production continues to be generated from conventional methods. The southern portion of the mine is moving to trackless development. However, equipment brought into the mine must be disassembled and moved in the shaft which is time consuming and labor intensive.

Tres Amigos remains a conventional tracked mine using mostly a modified shrinkage stoping method. The mineralized zones are narrow and high-grade making them well suited to these more selective stoping methods. The operation incorporates higher productivity methods where advantageous, such as auxiliary development and ramps driven with trackless equipment.

The processing plant at the Don Diego accepts feed from the Cabello Blanco deposit as well as toll feed from artisanal miners. The Don Diego process uses sequential flotation to produce 2 concentrates: lead and zinc. The mill uses a crushing, grinding, and flotation flowsheet to recover a lead concentrate and a zinc concentrate.

-

Geology, Mineralization & Exploration Potential

The Caballo Blanco district is located in the central block of the Cordillera del Este, in a sequence of Ordovician-Silurian sediments. Mineral deposits occur as structurally controlled, polymetallic, veins oriented NS, NNE-SSW and NNW-SSE, located in welded tuffs of the Kari Kari complex.

Main mineral species are marmatite, sphalerite, galena, and jamesonite, with lesser chalcopyrite and siderite. Vein thickness is typically 0.5-1.7M.

-

Mineral Reserves & Resources

Grade Contained Metal Tonnes

(kt)Ag

(g/t)Zn

(%)Pb

(%)Ag

(koz)Zn

(kt)Pb

(kt)Measured Mineral Resources 726 321 15.96 3.03 7,481 115.8 22.0 Indicated Mineral Resources 502 269 14.32 2.86 4,343 71.8 14.3 Measured & Indicated Mineral Resources 1,227 300 15.29 2.96 11,824 187.6 36.4 Inferred Mineral Resources 2,217 199 13.28 2.12 14,183 294.4 47.1 Proven Mineral Reserves 569 217 9.90 1.85 3,965 56.3 10.5 Probable Mineral Reserves 465 165 8.30 1.96 2,463 38.6 9.1 Proven & Probable Mineral Reserves 1,034 193 9.18 1.90 6,428 94.9 19.6 Notes:

- Caballo Blanco Group of Mines consists of the Colquechaquita, Tres Amigos and Reserva mines.

- The Mineral Resource estimate was prepared using a 10.0% zinc equivalent cut-off grade. Cut-off grades were derived from $25.20/oz silver, $1.38/lb zinc and $1.20/lb lead; and process recoveries of 92.1% for zinc, 77.2% for lead and 90.8% for silver.

- The Mineral Reserve estimate was prepared using a 11.9% zinc equivalent cut-off grade, using the formula ZnEQV = Zn% + 1.22 x Pb% + 0.051 x Ag (g/t). This cut-off grade was based on current smelter agreements and metal prices of $21.00/oz silver, $1.15/lb zinc and $1.00/lb lead, total OPEX costs of $106.94/t based on 2022 actual costs plus capital costs of $42.33/t, with process recoveries of 92.1% for zinc, 77.2% for lead, and 90.8% for silver.

- The effective date of the Mineral Resource and Reserve estimates at the Bolivian Producing Mines is January 1, 2023. Production data for the calendar year 2023 has been included in Section 24 of the various NI 43-101 compliant technical reports for the Bolivian Producing Mines and shows the depletion and typical replenishment of resources and reserves over a calendar year