Zimapan Mining District

-

Overview

The Zimapan mining district was discovered by Spanish miners in 1575. From 1632 to 1920, more than 18 mines were put into production, including the El Monte and Carrizal mines. Peñoles operated the mine from 1964 until leasing to Santacruz in August 2009. From 2011 to 2020, Santacruz completed ~30K m of underground drilling and mined ~5.9M tonnes of mineralized material from the El Monte and Carrizal mines.

With the addition of new underground mining equipment in October 2020 production throughput at the Zimapan Mine increased to 180,000 tonnes for Q4 and is on target to reach 200,000 tonnes by Q3 2021. Management anticipates that this improvement will have a positive impact on operating cash flows. Surface and underground infrastructure including electrical and other necessary infrastructure required for day-to-day operations. Zimapan processing facility has a capacity of 75,000 dry metric tonnes per month and zinc, lead and copper circuits.

-

Location

The mine is 34 mining concessions covering an area of 5,139 hectares, including the highly prospective 337-hectare Santa Gorgonia 1 concession. It is 7 km from the municipality of Zimapan in Hidalgo State, Mexico with excellent infrastructure with access via paved and dirt roads, water and grid power.

-

Geology & Mineralization

Located along the southern margin of the prolific Sierra Madre Oriental, 14 mineralization zones have been identified (six at Carrizal and eight at El Monte). High temperature carbonate replacement deposits containing Ag-Pb-Zn-Cu in semi-massive and massive sulphide bodies hosted in skarns (typically up to 20 m wide and up to 200 m long) and quatz-feldspar porphyry dikes

-

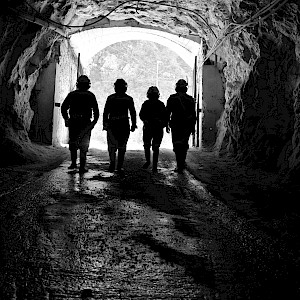

Operations & Infrastructure

The Carrizal and El Monte mines are connected by a 7.4 km underground access tunnel. Underground mining using cut-and-fill, long-hole and sub-level stoping (typically 15 m to 20 m panels) and room and pillar (typically 5 m height). A 3,200 tpd modern milling facility (conventional sulphide flotation) with three circuits for the production of high-quality lead, zinc and copper concentrates. Tailings dam with 5 years of capacity plus new permitted area with 15 years of capacity